Predge and LKAB collaborate in a strategic digitalization project

Predge AB and LKAB have jointly collabrated and applied for, and received, funding from *EIT RawMaterials to develop an innovative solution for condition monitoring and health prediction of Conveyor Belts. The project objective is to develop and validate an operational predictive decision support for operation and maintenance of conveyor belt systems realized on a digital platform and provisioned as SaaS. A system level approach is taken to understand wear and tear of critical components and to predict when the system will fail. The prototype uses a digital twin of the conveyor belt system combining domain knowledge with machine learning and AI principles.

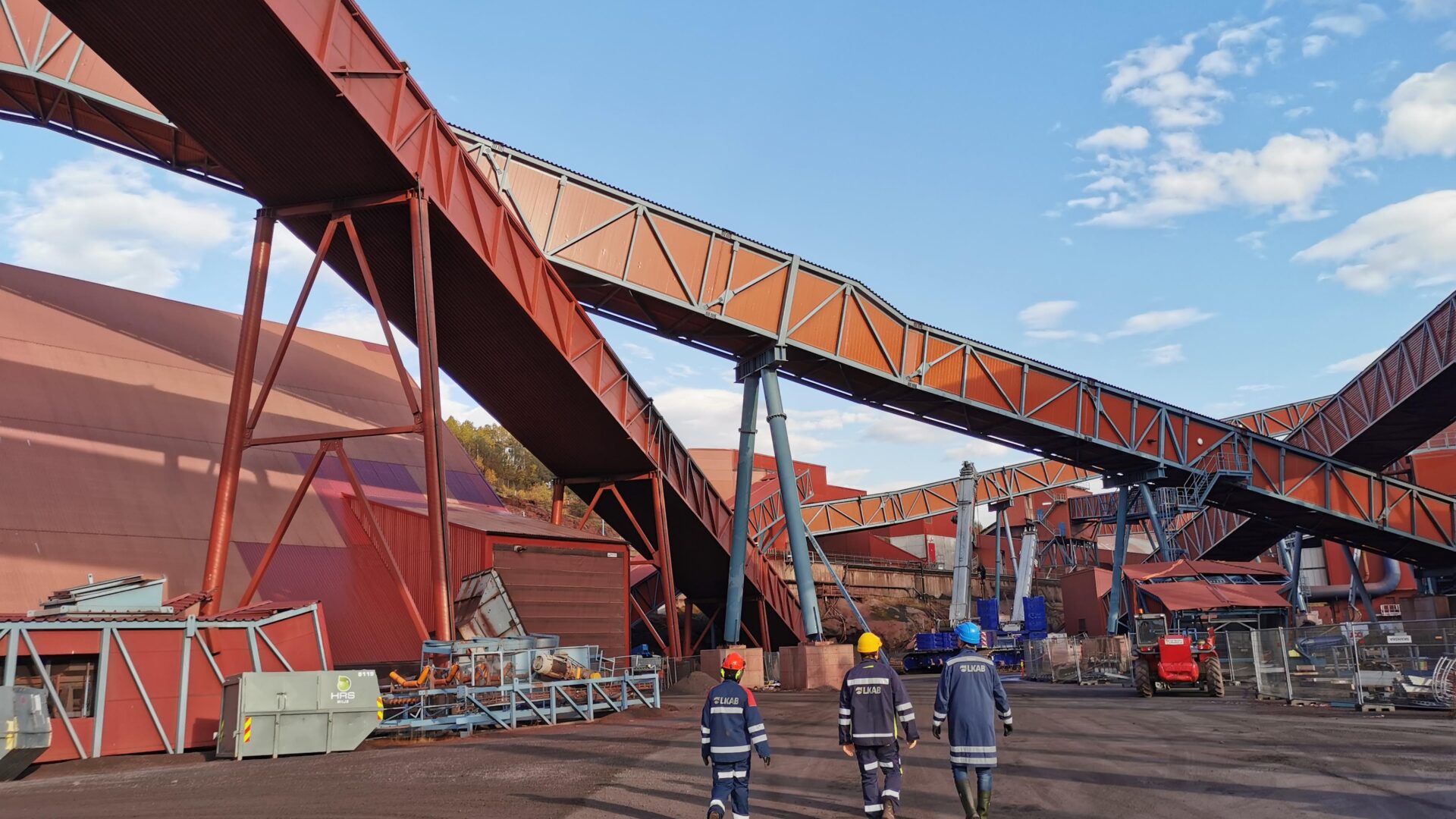

Conveyor belt systems are the arteries of many production lines and are critical in securing the material flow between processing units. Disruption of operation due to unplanned stops when a critical component fails leads to unexpected costs and in the worst case a stop in production and delivery to customers. Conveyor belt systems are used in virtually all processes industries, but also other sectors where bulk material must be transported. In mining operations, these systems are present throughout the complete production chain.

The need for condition monitoring and health prediction of conveyor belt systems (CBS) was identified in the **Rock Tech Centre (RTC) project MINDI – Predictive Maintenance (PM) as part of the Mining Data Initiative program (MINDI). The PM-project was conducted by Predge AB on behalf of RTC. The RTC project resulted in a system prototype that was tested on a CBS at the Boliden Aitik mining operation. The partners of the project agreed that the project results are promising and should be further developed, tested and validated. The key developers were researchers and engineers from Luleå University of Technology and Predge AB.

The project consortium consists of LKAB and Predge AB, where LKAB provides access and expertise on the facility for validating solution, and Predge AB provide the digital platform and the prototype. The joint effort targets a market-ready solution that increases utilization and reduces unplanned stops.

Both LKAB and Predge have been collaborating in several research and development project and have ongoing commercial contracts.

*EIT RawMaterials, initiated and funded by the EIT (European Institute of Innovation and Technology), a body of the European Union, is the largest consortium in the raw materials sector worldwide. Its vision is to develop raw materials into a major strength for Europe. Its mission is to enable sustainable competitiveness of the European minerals, metals and materials sector along the value chain by driving innovation, education and entrepreneurship.

** The Nordic Rock Tech Centre AB (RTC) was formed in 2005 aiming to reinforce competency and international competitiveness in the field of rock engineering and mining technology. RTC help customers to identify, initiate and drive innovation and development projects in collaboration with private companies, universities, governmental and research organizations. The primary goal is to create unique value and improve the business results of our project stakeholders. Since the start, RTC has been a non-profit company. The company is owned by the Bergforsk Foundation, Atlas Copco, NCC and ABB. Bergforsk Foundation is headed by Boliden Mineral, LKAB, Zinkgruvan and Luleå University of Technology.